Bandsawn Boxes

|

|

Resources

For Making Bandsawn Boxes

Resources

For Making Bandsawn Boxes

Band Saws

Clamps

Drill Bits

Drill Presses

Glue

Table Saws

BOX OF DRAWERS

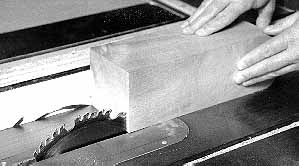

Large thick rectangles lend themselves to the drawer configuration, though they could just as easily be oriented horizontally with a long lid if you wish. To start a box of drawers, first square up all six sides of the rectangle on your table saw. Note that you need a piece over a foot long to do this safely. Then rip off a thin back as shown in photo 1, at about 5/16" thick. Set this piece aside.

|

|

Photo 1-

Begin a box with drawers by cutting off the back, which will be glued back on

after the drawers are cut out. |

Sketch the shapes of the

drawers you desire on the front face of the box. Remember that the radius you

can cut on the band saw is limited by the width of the blade you use. 1/8"

wide blades are available and they will cut very tight radii, but they break easily,

so I use 1/4" blades for my tight curve work. Do tests in scrap to see how

tight a curve you can cut, and use this as a guide as you sketch your drawers.

At the band saw, rip off

one side of the box, following the edges of the drawers you sketched. Then cut

out each of the drawer blanks as shown in photo 2.

|

|

Photo 2- Trace the drawers on the front face, then rip off a side following the drawer sides. Then cut out the drawer blanks. |

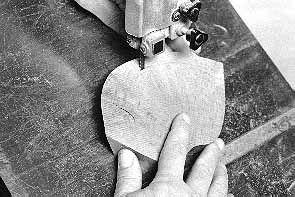

The next step is to rip off

both the front and back of each drawer blank. Make each of these about

5/16" thick or so. As you do this, tilt the piece while it is being cut so

that the area immediately below the blade is always touching the band saw

table. If you don't do this, the blade could grab the work and throw it down

quickly, causing an accident. Keep your fingers out of the path of the blade,

and keep your eye on what you are doing.

|

|

Photo 3-

With the band saw cut off both the front and back of each drawer, then cut

out the cavity of each as shown here. |

Mark the front and back

pieces of each drawer so you remember where they go. Sketch the inside drawer

contour onto the remaining drawer blanks on their front faces and cut them out

as in photo 3.

|

|

Photo 4-

Glue the carcass and drawers back together, carefully aligning the parts to

each other. |

Glue up the box carcass and drawer parts as in photo 4. Use a lot of clamps to evenly distribute the pressure. When out of clamps, round over the sharp edges and sand or scrape the exposed band sawn surfaces. Finish to your liking and install pulls that please.

SWIVEL LIDDED BOX

How you proceed with boxes

made of rough pieces such as this will depend upon the shape of the piece you

have and what you want to do with it. I'll describe how I made this one, but

feel free to alter the procedures to suit your wood and taste.

This gnarly burl was crying

to be made into a box so that it could retain its rough exterior while showing

us its figured inside. The first thing I did with it was to cut away the

remaining section of attached trunk on the band saw, then assessed how best to

orient the piece as a box. I decided to make the largest flat area into the lid

so that viewers would see the beautiful burl figure on top.

|

|

Photo 5-

On an uneven chunk of wood, first make flat surfaces as I did by making

careful cuts on the bandsaw, referring to a fence. |

I flattened the broad area that

was to be the top with a belt sander and rough grit to eliminate the chain saw

marks it had, then cut off the bottom of the box as in photo 5. By holding the

flattened top against a fence as shown the bottom came out parallel to the top.

|

|

Photo 6-

For a swivel-lidded top, bore a hole from the bottom toward, but not through,

the area that will be the top. Then cut the top off at the band saw, exposing

the bottom of the hole into which you can glue a pivot dowel |

Next I bored a 1/2"

hole for the swivel top to pivot upon as in photo 6. I carefully set up the

drill press so that the bit would stop at 1/4" from the drill press table

top, and made the cut from the box bottom as shown. This way the hole didn't

come through the box top.

Then, back at the band saw,

I cut off the lid at about 9/16" thick. This left about 1/4" or so of

the 1/2" hole in the underside of the top. Into this I glued a 1/2"

dowel about 1-1/2" long for the top to swivel upon. To ensure that the

dowel was oriented correctly, I placed it in the box carcass after gluing the

other end in the top, and checked to see that the lid was parallel to the

carcass.

|

|

Photo 7-

Now cut out the body of the box. Tilt the band saw table if necessary to

accomodate the |

To cut out the front

portion of the carcass body I tilted the band saw table to match the angle of

the rough surface, as in photo 7. But the back portion of the carcass was at

right angles to the top and bottom, so I made a separate cut with the table at

90o for that section. This released the central core. From this core I got two components;

the box bottom and shelf. The bottom I cut off with a fence to regulate its

thickness as in photo 8.

|

|

Photo 8-

This shot shows the central chunk cut out from the body of the box. I'm

cutting off the bottom of it to use as the box bottom. Next, I'll cut off the

top of this chunk to make the shelf. |

I made a similar cut to get

the blank for the shelf. Then, I cut off a thin section from the shelf bottom

to make up that part, and began to cut out the cavities for the shelf. Once

again, I had to make one cut with the band saw table angled as in photo 9 for

the shelf front. The other cuts I made with the table at 90o to complete the

shelf.

|

|

Photo 9-

To cut out the body of the shelf, I once again needed to tilt the band saw

table to match the angle of the front of the drawer piece. |

Because of the thickness of

the band saw kerf, the bottom fit loosely within its space. But, because the

front was angled, I was able to drop the bottom down a bit and wedge it in

place during the glue up. When the glue was dry I flattened the bottom by

sanding.